Testing, Testing...

- Maxine Callow

- Dec 15, 2025

- 4 min read

Updated: Jan 8

Yes, it's testing. Testing my patience and my understanding. Glazing. As previously noted in another blog, glazing is my least favourite aspect of ceramics. I think it requires a set of skills that I thinly possess. I’m doing my utmost to learn as much as possible about glazes that I require, but I seem to make little progress.

I’ve decided on an end product. I want my stoneware to look dirty with a matte surface. There will be relevant colours applied depending on the piece. You’d think backfilling those requirements would be simple. You’d be wholly incorrect! Let’s break it down.

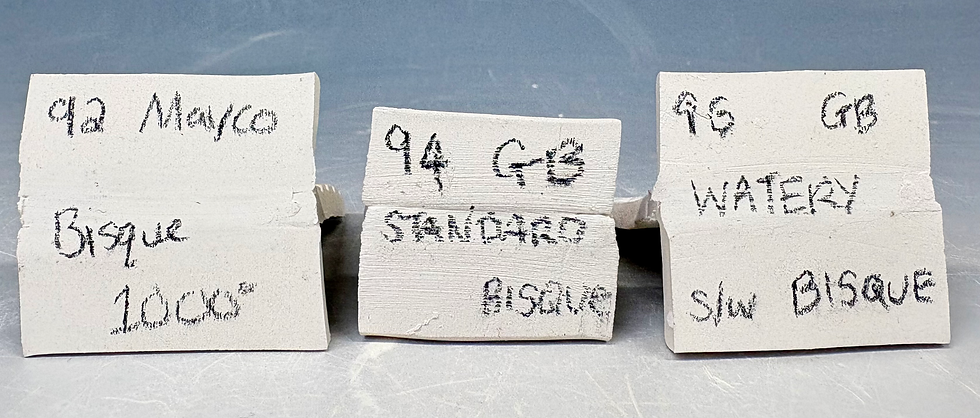

Underglazes are the obvious choice to provide me with colour. I’ve tried these in various forms and at varying stages. Yes, you can apply to leatherhard clay, but the results can prove inconsistent. I have learned it is better to apply them to bisque for a more reliable, repeatable result. Next is the variable consistencies and the amount of stain involved. Some colours require a tiny amount of stain, so strong is the pigment, others require a hefty amount. This means each colour requires test tiles before applying the underglaze to a finished piece.

For some of my work, I would like a watercolour effect and so I’ve been testing watercolour underglazes with various pigments. The results have been incredibly varied, and I remain unimpressed with the achieved results. Patchy looking ceramics is not my intention. I have concluded that watercolours are not as important as how the piece looks, and a solid underglaze will suffice.

So, there lies my underglaze results thus far. If we were to measure it on a ruler, I suspect we’d still be measuring in millimetres.

Next up is the dirty effect. The obvious choice is an oxide and as I want black, then manganese or copper are my focus for testing. Manganese is almost there but can be a tad brown. Copper is great but it can end up with a slight sheen that is undesirable. I’m wondering if a black stain wash may be more what I need. The jury is out on this one and further testing will need to be performed.

Finally, a simple matte, transparent stoneware glaze to seal the surface is my final requirement. This sounds so easy when put on the list of requirements. How wrong can you be? I am now on the hunt for glaze number five as the first four all have issues: they turn the oxide green, they remain shiny, they turn milky, they are patchy. It is possible to get around some of these issues, but as every one of them seems to have the shiny issue, then it is pointless to keep firing to varying temperatures to check the interactions with the oxides or the underglazes. Maybe Santa will bring me a glaze recipe for Christmas. I’m sure I’m on his Nice List…

Applying all these finishes brings forth further variables. Should I dip, brush or spray? Historically, dipping has always given me very patchy results indeed. There are runs, inconsistent thicknesses of glaze, and corners missing glaze completely. The time saved by dipping is taken up with repairing the unfired glaze post dip. I may as well have brushed it on in the first place. Spraying can be better, but you need a booth which I have at university, but not in my home studio. It may just be better to rule this out at this stage as I cannot keep it up further down the line. So, by process of elimination, brushing seems to be my way forward. Working with this method means I can get a solid colour if desired, or a watery style if needed. I’m saving no time, but I do feel more in control.

Finally, to add to the mix of the variables already discussed, we throw in firing. One fire for bisque, one for underglaze, another for oxide and a final fire for the top glaze. And we all know that kilns are a law unto themselves and add more variables than you can shake a stick at. Currently at university, I’m using a communal kiln shared by many and operated by Cath, our fabulous technician and a ceramic artist in her own right. Things generally go to plan, until they don’t, and then it’s a case of making adjustments, starting again and trialling temperatures, soaks, holds and heatwork.

When all of this is tallied up and the variables are mixed together, I don’t have the mathematical capacity to calculate the numbers involved. What I do know, is that it’s easier just to pray to the kiln gods, consider luck as an option, and accept that glazing is not my friend.

Comments